Product display

当前位置:首页> Product display

Our services

-

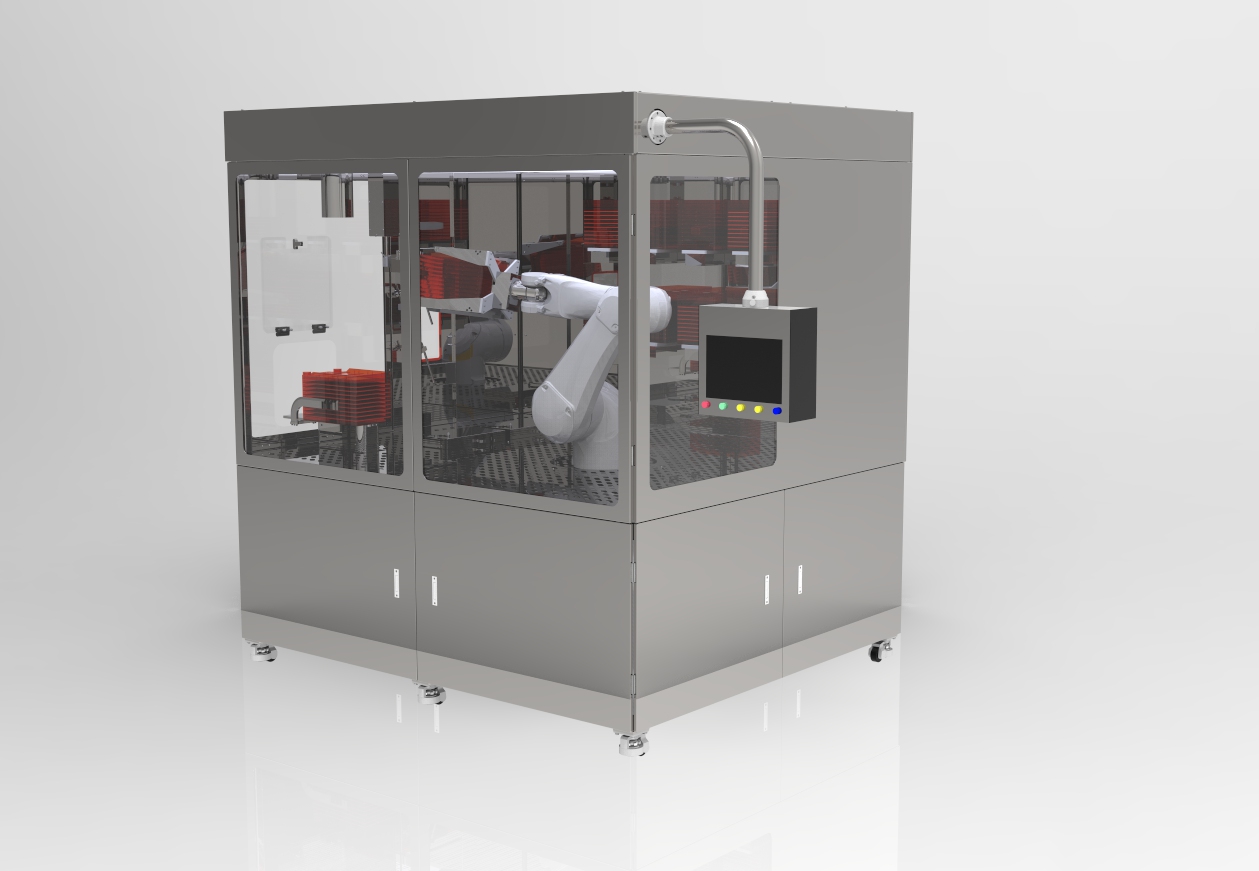

10 layers cell factory automation workstation

Ten layers cell factory automatic station is applicable to the automatic culture of ten layer cell factory, and can realize the whole process unmanned operation of automatic liquid filling, automatic liquid homogenization and automatic liquid discharge. The above process flow can act alone, with higher flexibility and richer adaptation to the scene.

-

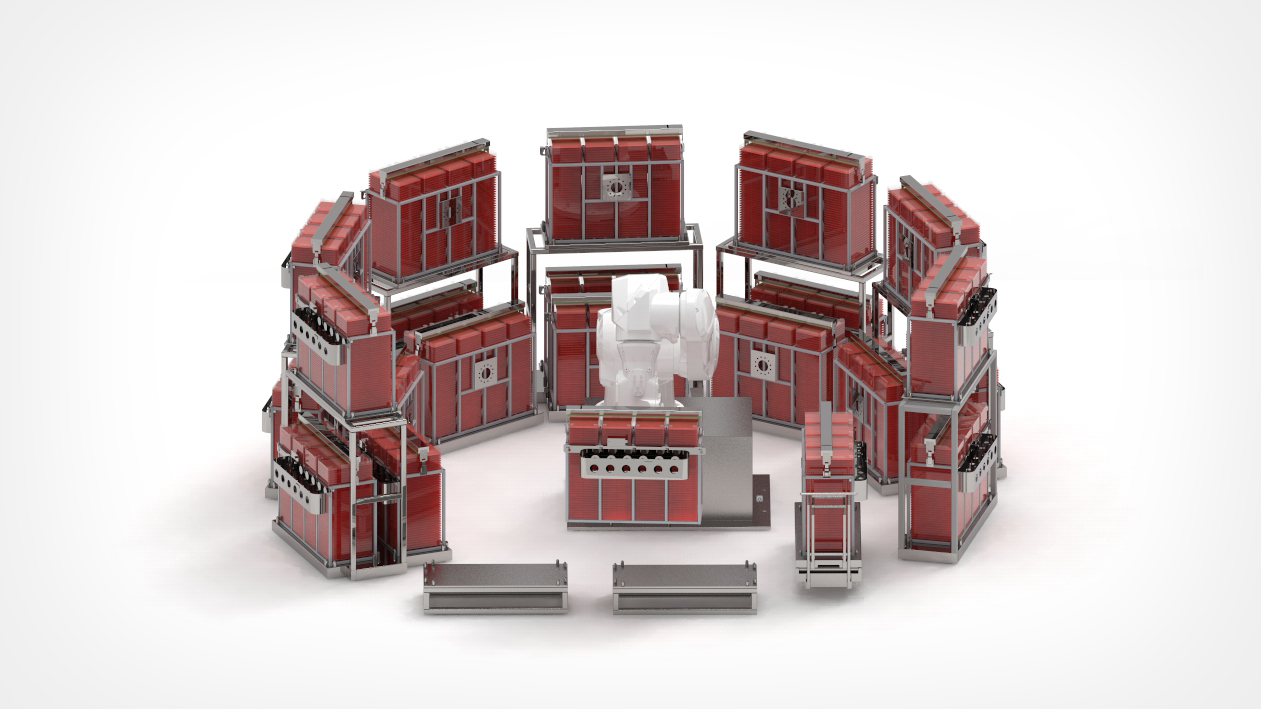

Automated biopharmaceutical equipment

Automated biopharmaceutical equipment|CFAM cell factory automation equipment|

-

Cell mixer

The cell mixer can realize the weighing and stirring of the cells, so that the cells are fully uniform and high-precision weighing.

-

Aseptic filling equipment

This equipment is specially designed for filling bottles in an aseptic environment. Among them, automatic bottle unscramble, automatic bottle feeding, automatic filling, automatic capping and capping are high-tech filling equipment integrating machine and electricity. It has a high degree of automation and is applied to aseptic filling of bottles. This system is specially designed for customers. B

-

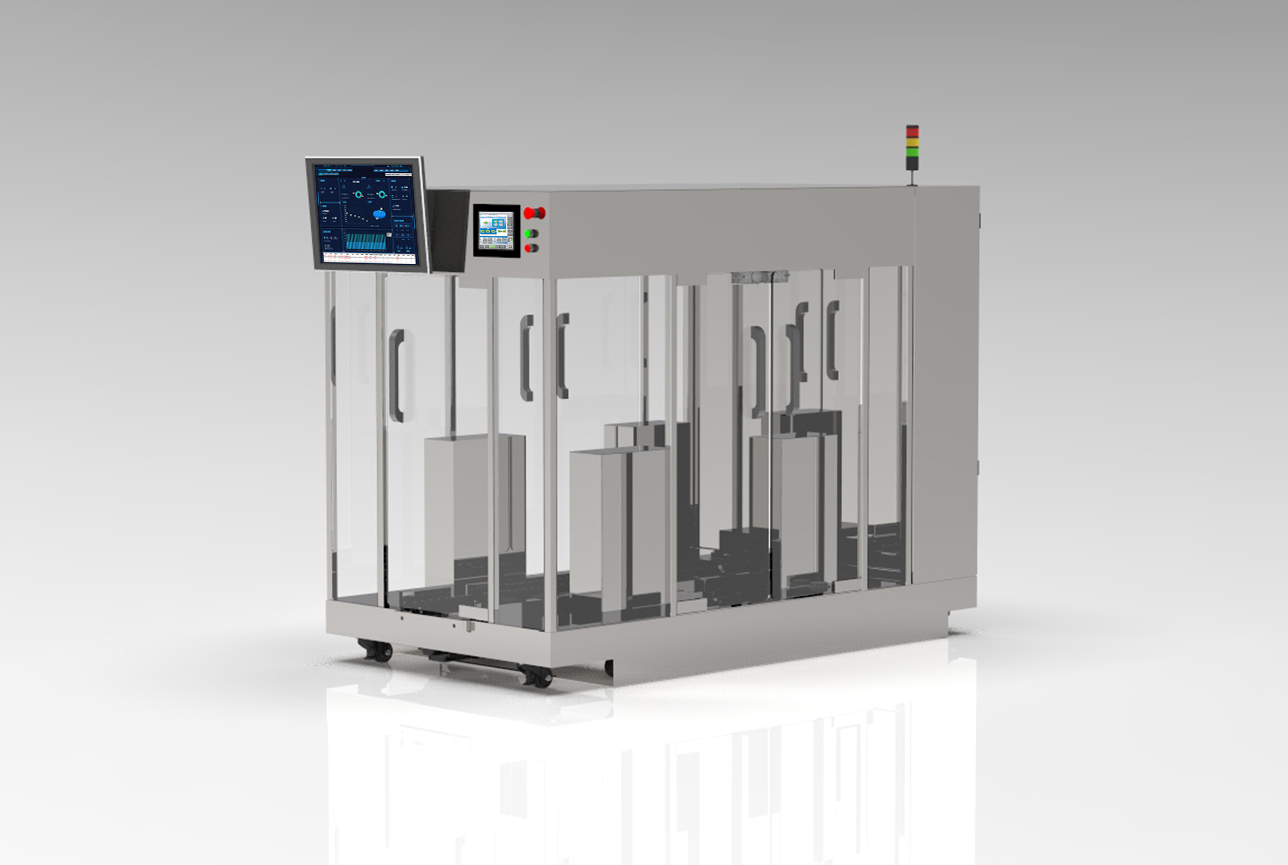

Multilayer cell culture microscope observation equipment

The operator observes the culture in the multi-layer culture container, can observe the upper and lower surfaces at the same time, and the number of observation layers can reach 3 layers. Under software optimization, images can be simultaneously imaged in the display, which is convenient for operators to operate and observe. The visual system observation magnification can reach 100 times, and the

-

Robot packing and palletizing equipment

Robot Packing and Palletizing Equipment|Can complete unpacking, packing, certificate placement, sealing, three-phase code printing, labeling, and palletizing functions|

-

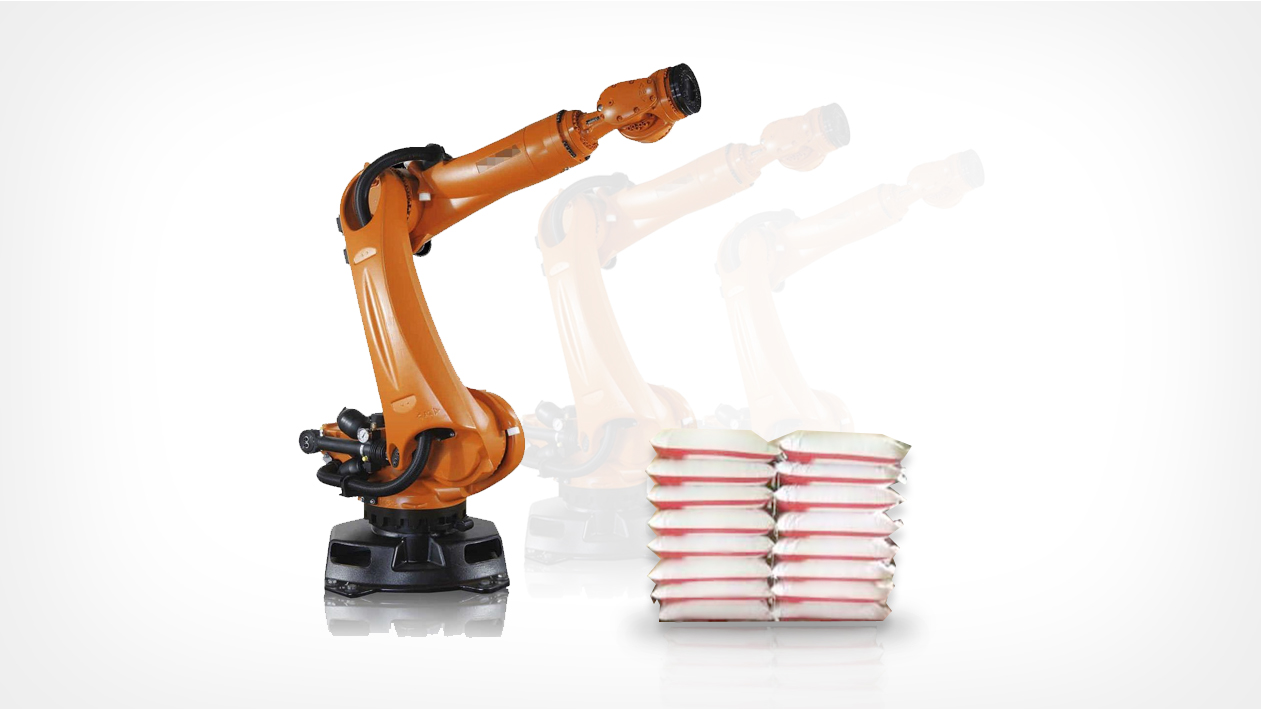

Depalletizing robot equipment

Depalletizing robot equipment | 3D vision accurately obtains the stacking posture, and guides the robot system to complete a series of tasks such as depalletizing, bag breaking, transfer, packaging collection, etc.|

-

High-speed loading and unloading sorting robot

High-speed loading and unloading sorting robot | can quickly and accurately locate and sort the materials according to the color, size, shape, and placement position of the material for grasping and sorting work |

-

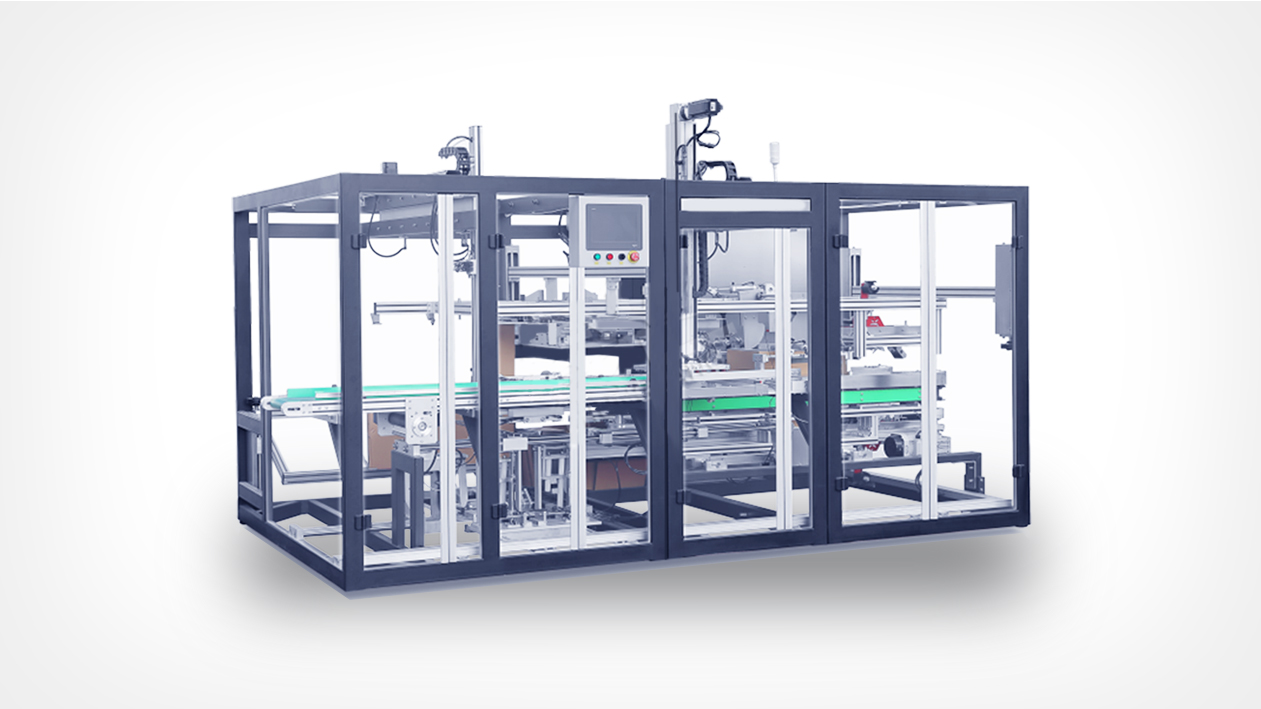

KZF550 unpacking and sealing all-in-one machine

KZF550 Unpacking, Packing and Sealing All-in-one Machine|Automatically realize the functions of unpacking, packing and sealing|

-

Six-axis robot loading equipment

Six-axis robot loading equipment in processing workshop|The robot automatically completes the work of grasping, loading, unloading and collecting finished products to the designated location|

-

Digital factory SCADA software

Digital factory SCADA software|SCADA data monitoring and management software meets the requirements of GMP regulations for production data collection and storage|

-

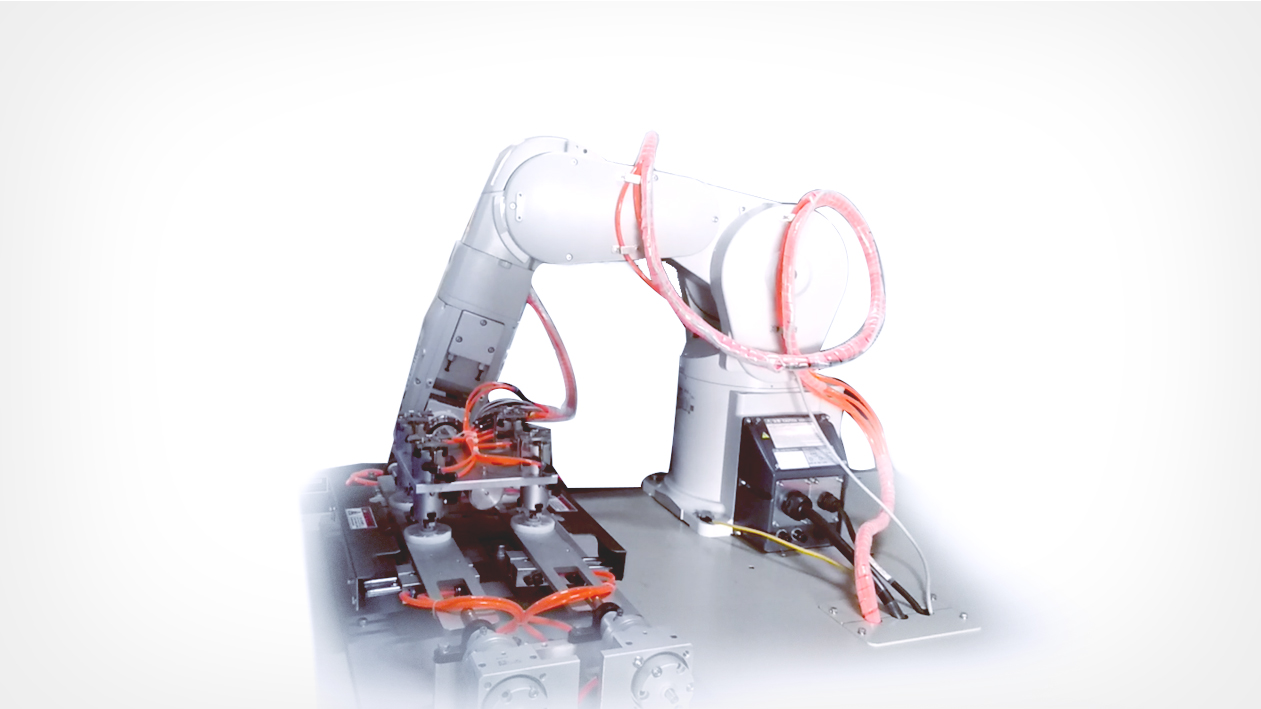

Robotic arm

Robotic Arm|Realize the functions of unpacking/packing/certificate placement/sealing/three-phase code printing/labeling/palletizing and other functions|